Your trusted partner for Data Centre noise control & visual screening solutions

Integrated Acoustic Louvres, Weather Louvres, Panels & Attenuators designed, manufactured & installed for mission-critical facilities. All backed by our trusted experience in this complex and evolving market.

Acoustic Consultancy

Background noise surveys to establish suitable external noise criteria for planning.

Find out more

Acoustic Enclosure

Designed to prevent noisy equipment from disturbing the surrounding environment.

Find out more

Acoustic Louvre

Controlling noise to defined targets whilst allowing the passage of air.

Find out more

Acoustic Louvre

Controlling noise to defined targets whilst allowing the passage of air.

Find out more

Integrated Attenuator

Close coupled integrated attenuators offer noise levels as low as NR25.

Find out more

Integrated Attenuator

Close coupled integrated attenuators offer noise levels as low as NR25.

Find out more

Fan Coil Unit

A quiet energy efficient design, selected to achieve specific noise targets.

Find out more

“Caice’s creativity, enthusiasm and strong project management skills helped us to achieve precisely what we wanted, within our budget.”

- John Belton, Program Delivery Director, Infinity SDC

Trusted by leading Data Centre operators with projects £1m+ in scale

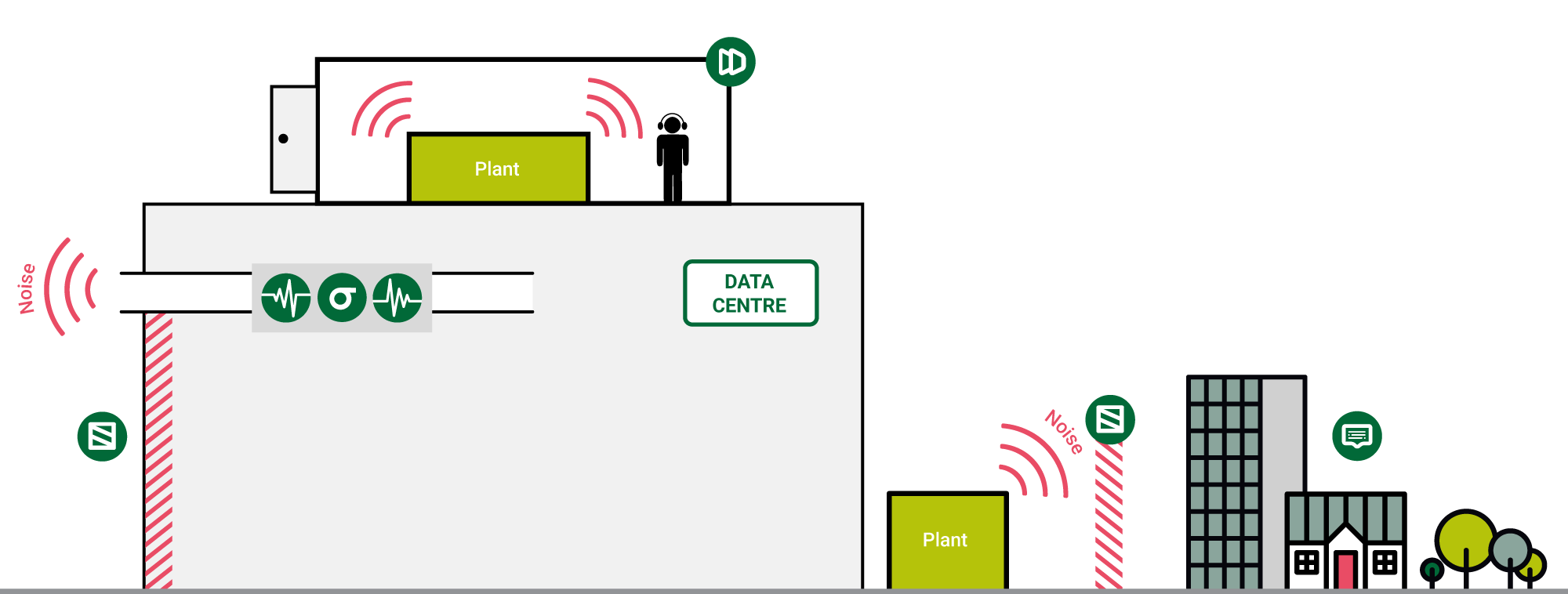

Everything fits together

In seamless solutions

Overcoming noisy & aesthetic challenges

Data centres are expanding fast – and with them, the challenges of noise control. From cooling systems and generators to planning compliance and protecting uptime, the acoustic environment is now critical to project success.

Downtime costs £ thousands per minute

With proven products, robust testing and extensive site experience, we help you minimise risk at every stage.

Avoid delays & unnecessary costs

Noise control issues discovered late can derail planning approval and add significant costs. By involving us from the outset, you get practical, compliant solutions built into the design — saving time, budget, and stress later.

Many years of experience

Since 2012 we have helped architects, consultants and contractors deliver reliable, compliant, and future-ready data centres.

Reach your sustainability targets

At our fully integrated Production Centre we continue to drive down unnecessary costs, drive up manufacturing efficiencies, as well as reduce the embodied carbon in all of our products. Helping you to reach your environmental, sustainability & carbon reduction targets.

"The most successful projects are where architects or designers engage with us right at the beginning.”

- Mark Evans, Associate Sales Director Caice

MCR2 Teledata Manchester Data Centre

This installation of acoustic louvres delivered the acoustic performance to protect the surrounding community and the aesthetic intent of the architect. Despite overcoming several technical and coordination challenges plus late design changes.

Why noise control matters in Data Centres

Noise in data centres is complex

High-density cooling produces constant fan hum, generators add broadband noise, and urban locations mean having sensitive neighbours.

Costly delays if not managed early

Add to that the fact that UK planning authorities apply BS 4142 context-based assessments – not fixed limits – and you have a recipe for costly delays and design changes if noise isn’t managed early.

Less risk & faster planning approval

Working with us means less risk for you, faster planning approval, and long-term operational reliability. Here at Caice, we combine consultancy, manufacturing and installation into one seamless package – giving you certainty at every stage.

Screening Weather Louvres for planning & aesthetics

Not just noise, it's appearance too

In many UK data centre projects, the challenge isn’t just noise – its appearance. Large-scale plant such as generators, hybrid chillers, air blast coolers and HVAC systems can dominate skylines and clash with local architecture, particularly in sensitive rural or residential areas.

Visual mitigation for planning approval

Local authorities frequently require visual mitigation as part of planning approval, making external screening just as important as acoustic control.

Far less impact on neighbours

Beyond compliance, thoughtful screening reduces visual impact, fosters positive neighbour relations, and helps data centres demonstrate their commitment to environmental and design responsibility.

Designed to blend, built to last

Our Weather Louvres are engineered to conceal essential plant while maintaining airflow performance. By integrating louvres into façades, contractors and consultants can achieve a clean, consistent aesthetic that satisfies planning conditions and reassures local communities.

"Our installations will probably outlast most of the Data Centres, due to developments in both data centre technology and HVAC products.”

- Mark Evans, Associate Sales Director Caice

Hemel Hempstead 4 Data Centre

A smooth and successful weather louvre screening project for a data centre containing 4,800m2 of server space and a maximum IT load of 12MW.

Proven success in Data Centres

We have delivered acoustic solutions for some of the UK’s most high-profile data centre developments.

Technical expertise with practical delivery

These projects demonstrate our ability to combine technical expertise with practical delivery – giving architects, consultants and contractors confidence at every stage.

Reducing risk & keeping projects on track

From early-stage modelling through to large-scale manufacturing and on-site installation, our approach is proven to reduce your risk and keep projects on track.

"We manufacture up to 90 % of our products from standardised modules, speeding up manufacture and installation.”

- Mark Evans, Sales Associate Caice

Discover how we design and manufacture + why it matters

To maintain our pioneering leadership in Acoustic and Air Movement products

of Acoustic Louvres manufactured for Data Centres to date

That would cover nearly 2.5 football pitches

See how we work

For a professional installation on time, all our systems are fully integrated.

Yondr A Data Centre, Slough

Working on a congested site with strict schedules and complex crane operations, our flexible programming, precise planning, and tailored engineering delivered a bespoke acoustic louvre system. Completed on time, safely, and to exacting quality standards.

We've installed

of Weather Louvres on Data Centres to date

The same distance as London to Newcastle

Stage 1: Awareness

Identifying the challenges early

Noise assessments for data centres are complex. UK planning relies on context-based assessments to BS 4142, which considers prevailing noise levels and impact on the local community.

Avoid delays & redesigns

Too often, acoustic issues are only raised late in the project – leading to delays and redesigns.

Use our Acoustic Consultants

Through our in-house acoustic consultants, LCP Acoustics, we provide early-stage consultancy to ensure planning applications run smoothly. Helping you understand cumulative impacts, anticipate future expansion, and design holistic solutions that make compliance straightforward from day one.

Thermal & Acoustic test laboratory

Our in-house Thermal & Acoustic Test Laboratory ensures every product meets the highest acoustic standards, giving you complete confidence in performance.

Fire testing to BS EN 13501-1:2018

Our Acoustic Louvres have been fire tested to allow classification to BS EN 13501-1:2008

Stage 2: Specification

Balancing noise, airflow & aesthetics

Designing for data centres means tackling competing priorities: effective cooling, secure airflow, urban integration, and acoustic control.

Overcoming your challenges

Low-frequency hum from fans can travel long distances, while high-frequency broadband noise needs specialist treatment. Add visual impact into the equation, and the challenge becomes even greater.

Designed & manufactured from GA data

Every product is designed and manufactured directly from GA data using our 3D CAD system – so you can coordinate into your building model, reflecting our work on your site.

Stage 3: Procurement

Reducing risk & increasing certainty

Procurement teams face pressures to balance budget, compliance, and speed of delivery. Demonstrating ROI for acoustic solutions, securing warranties, and meeting documentation requirements can feel complex.

Fewer headaches with one provider

Procuring multiple products from a single provider means fewer headaches and simpler for you. Supported by transparent performance data, robust test results, and full compliance with BS 4142 and other relevant standards.

Everything is transparent

With transparent data, consistent quality, and guaranteed performance. All our products are tested and verified independently, with full documentation. With guaranteed compliance with BS 4142 and EN standards.

What is costed is what is delivered

Because every product is manufactured at our Production Centre from coordinated GA drawings, what is costed is what is delivered – minimising risk and variation costs. Guaranteeing consistent quality from design through to delivery.

Confident in meeting peak demands

Our UK Production Centre has been designed to meet the biggest peaks in demand so you can be confident we’ll meet your most demanding programme schedules.

Over-capacity designed-in

Our integrated UK Production Centre has resilience and our in-house paint line has over-capacity designed-in, to comfortably meet the peak demands of large scale projects.

Proactivity pays when working at large scale

Due to the large scale of data centre projects we do things others don’t. Our project managers maintain programme certainty, proactively checking deliveries, surveying ‘make up pieces’ and resolving issues before they affect progress.

Stage 4: Implementation

Installing with confidence

Acoustic solutions must fit seamlessly into compact plant areas, integrate with cooling systems, and allow for last-minute design changes. Quality installation is critical to performance.

Success starts way before getting to site

Planning, communication and coordination begin well before arrival on site. Our experienced project managers, draughtsmen and sales teams ensure designs are reviewed and understood, so installation progresses smoothly.

On site, time & space are tight

We work closely with contractors to ensure delivery is smooth and stress-free, with our technical support team on hand throughout – just in case. Our drawings are detailed and transparent, ensuring contractors know exactly what to expect — no hidden extras or omissions.

Clear instructions for installation

Installers really appreciate that everything arrives as specified, manufactured to fit seamlessly on-site for a straightforward installation. Based on clear installation instructions and sophisticated logistics support. Which means they always cost competitively when working with us.

Going home fit & healthy each day

We also prioritise Health & Safety management. Module size and weight are assessed on every project, and where necessary we specify smaller units or mechanical lifting to protect installation teams — sometimes at a slightly higher cost, but always the safer choice. Our detailed H&S processes and documentation are often praised for the thought and detail as we want the installation teams to go home fit and healthy at the end of every day.

Keeping your project on track

With decades of experience in Data Centre construction, we understand the pressures of site coordination and can help you keep projects on track.

Doing whatever it takes

You avoid delays because we always take ‘digs’ close to sites and work weekends where necessary. There have been many times when our team’s rapid adaptation to issues on site, has ensured critical installations continued on schedule.

Stage 5: Post-Implementation

Long-term reliability

Data Centres operate 24/7 — acoustic solutions must match that resilience. Ours exceed them. With modular design, and continuous product improvement from on-site feedback, for the longest life and reduced maintenance risk.

Easy access for on-going maintenance

Acoustic solutions must perform reliably under continuous use and allow for easy access to equipment for maintenance.

Managing additional noise sources

As sites expand, additional noise sources must be managed to avoid breaching limits and triggering complaints from neighbours or the local community.

Solutions built to evolve & to last

Our solutions are built to last, supported by clear warranties and guidance for maintenance. Our consultancy team can also re-evaluate acoustic strategies as facilities evolve, ensuring ongoing compliance and community reassurance.

"It's our duty of care to make sure people are safe on-site and doing things properly."

- Ben Beresford, Special Projects Director Caice

Here East Data Centre, East London

Like all large Data Centre projects, the scale meant that we had to provide the installation team with what they needed precisely when needed. A wrong delivery could cost half a morning if they had to relocate to another part of the large site to work.

Data Centre operators choose us

As listed in DataCentre magazine, August 2025

Accreditations, testing & quality

Our reputation is built on trust and verification by working to the highest standards, including:

- Pre-qualification accreditations and Audited Health & Safety

- In-house validation at our Thermal & Acoustic Test Laboratory

- BS EN ISO testing across product ranges

- Rigorous safety culture across all projects

Data Centre success stories

Caice completes another Data Centre project in Berkshire

Bespoke Louvre Screens & secure Acoustic Doors setting a new standard for future Data Centre projects.

Caice delivers complex Acoustic Louvre installation for Yondr Data Centre

Complex acoustic and air movement solution within a dynamic and congested construction environment.

Seamless Acoustic Louvre integration for MCR2 Manchester Data Centre

Seamless Acoustic Louvres for noise control & architectural consistency.

Caice 3,000 m2 weather louvre screen for NTT DATA, Hemel Hempstead 4 Data Centre

Design, manufacture & installation of a 3,000 m2 weather louvre screen.

Here East Data Centre, East London

A unique engineering project featuring the supply and installation of our continuous line acoustic louvre system at Infinity Here East Data Centre in East London.

Thomson Reuters Data Centre, East India Docks, London

Working with our client KeyClad, Caice designed & installed a louvre system to screen generator and chiller plant equipment from view.

Data Centre resources

Useful links & documents

Ready to talk?

Whether you’re a consultant planning for compliance or a contractor focused on delivery, Caice is here to help. Discover how we can make your next project a success.