Proven products from our Thermal & Acoustic Test Laboratory

Have confidence that our products will perform

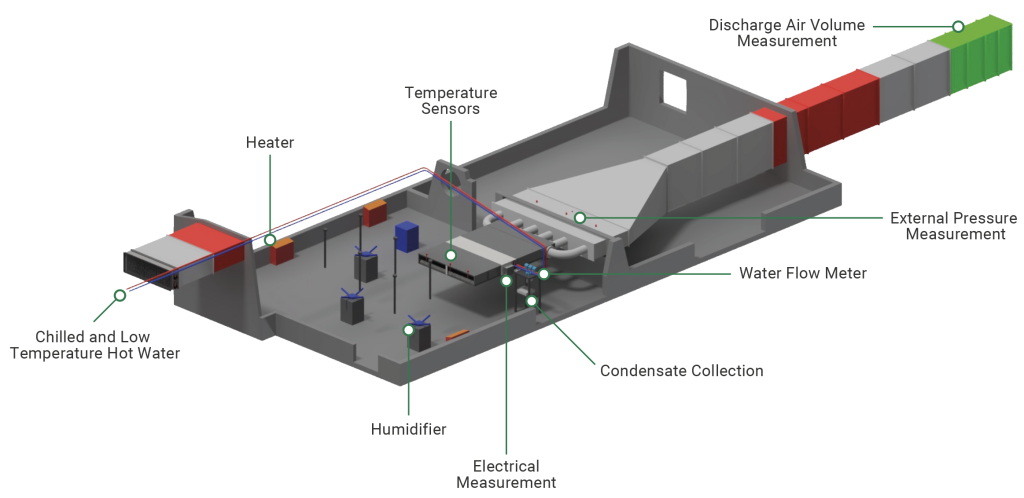

Our team of professionals operate our thermal and acoustic test laboratory at our dedicated facility in Dorset on Fan Coil Units (FCUs), Attenuators and Acoustic Louvres.

Fan Coil Unit tests

Our laboratory is the most advanced thermal and acoustic testing laboratory in the UK for FCUs and has been developed in collaboration with BSRIA. Sophisticated tests are conducted in the same chamber and results available immediately.

Designed and Commissioned in collaboration with BSRIA

BS EN 1397: 2021 Heat exchangers – Hydronic room fan coil units – Test procedures for establishing the performance.

BS 4856-4: 1997 Methods for testing and rating fan coil units, unit heaters and unit coolers. Determination of sound power levels of fan coil units, unit heaters and unit coolers using reverberation rooms.

BS 8850: 2020 Fan coil unit performance. Determination of specific fan power.

Reassurance and peace of mind that FCUs will meet your specified noise criteria

The test report compares the tested performance data with confirmed data provided to clients. The report also shows that the specified noise criteria for the project is met by the new Caice FCU DesignCalc software automatically inserting the tested noise data for the FCU into the acoustic calculation.

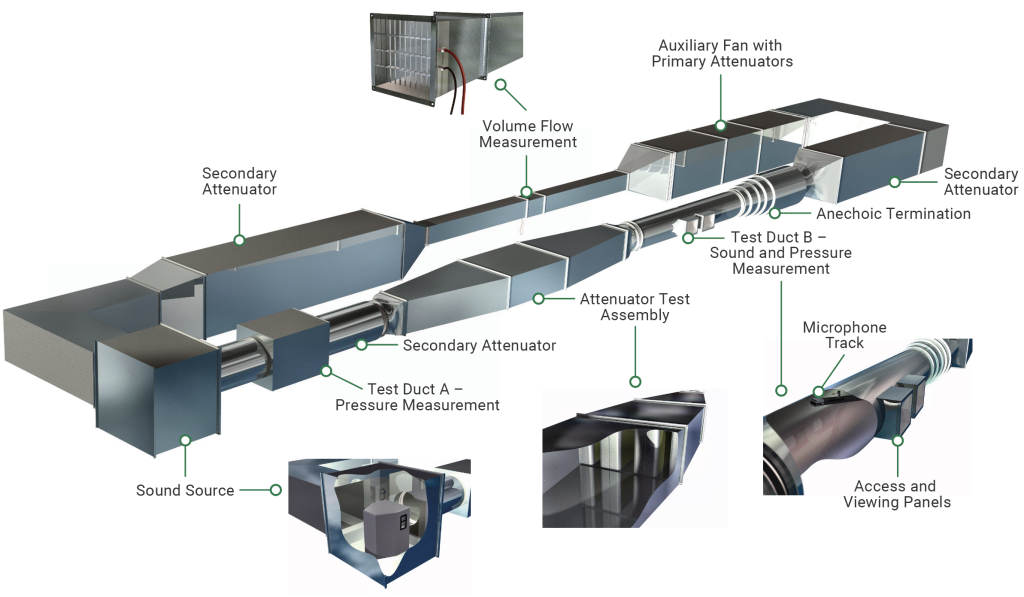

Attenuator and Acoustic Louvre tests

BS EN ISO 7235: 2009 “Acoustics – Laboratory measurement procedures for ducted silencers and air terminal units – insertion loss, flow noise and total pressure loss”.

Achieving your noise targets

To underline our commitment to provide quality acoustic performance data to assure we achieve your noise targets

Accurate pressure drop data in accordance with BS EN ISO 7235: 2009 ensures your plant provides the performance it was designed for

Clients save time when they witness tests and have a factory tour

Improved experience with greater speed and transparency

We have improved the whole experience for clients with greater speed and transparency when they combine witness tests and a factory tour.

- Tour of Production facilities

- Explanation of the thermal and acoustic testing process

- Witness tests being undertaken

- View test results immediately afterwards

- Reassurance that products meet specified noise criteria for your project

“We are very proud of what is undoubtably the most advanced Fan Coil Unit thermal and acoustic testing laboratory of its kind in the UK developed in collaboration with BSRIA. With the expansion and on-going investment in our dedicated FCU factory, this shows our confidence and commitment to the FCU market” says Mark Macdonald, Managing Director, Caice Acoustic Air Movement

Accurate data is at the core of what we do

“Caice is supplying so many Attenuator and Acoustic Louvre products into the Construction Industry, it’s vital both we and our clients are confident in the acoustic and airflow performance” says Duncan Powell, Sales Director, Caice Acoustic Air Movement