Keeping the BT brutalist building look, the noise down and neighbours happy with Acoustic Enclosure and Screening solution

BT Colindale Telephone Exchange refit has neat visual solution

The site is a large switching centre originally built by British Telecom in the 1960’s, which was being refitted with new state of the art communication systems by Sudlows, an international award winning infrastructure specialist.

Caice commissioned to design and install acoustic solution for brutalist building

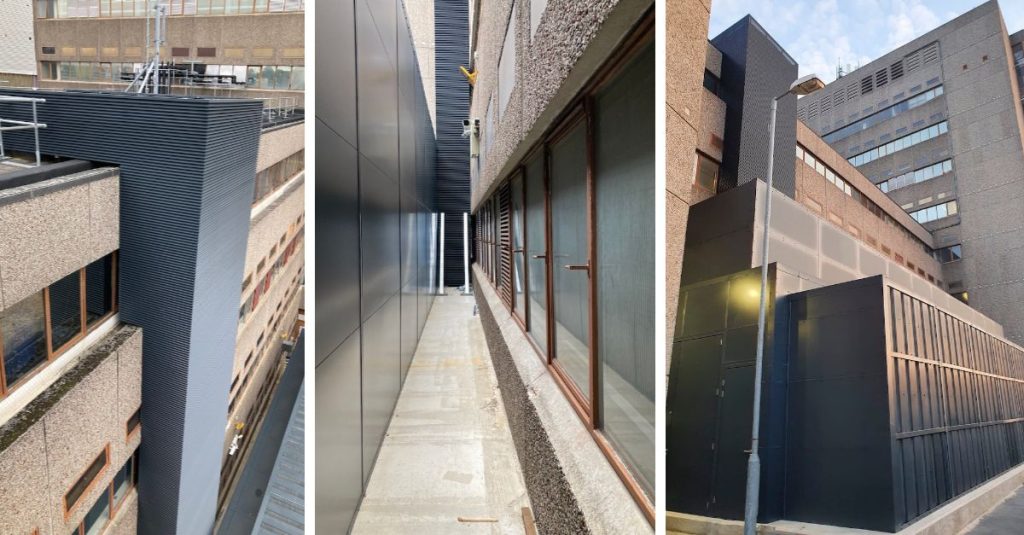

New chiller plant and service areas were required and Caice was commissioned to design, manufacture and install an acoustic enclosure and screening solution that would maintain the aesthetically pleasing appearance and match the brutalist architecture of the existing buildings. As well as meet the acoustic requirements for the new residential areas, converted from the old BT office blocks that form part of the Barnet Council regeneration scheme for new housing.

Design works from the ground up

Caice was commissioned to undertake design works on this project from the ground up. The full scheme was draughted by the Caice team before enlisting sub-contractors to assist in some of the finer details.

Full total station survey of the building

This was undertaken by Caice sub-contractor 3 Delta Design. This provided us with detailed survey dimensions of specific levels and areas of the existing building that would not have been possible using manual survey equipment.

Structural slab and drainage design

Although not a Caice core service, our ability to provide it for this project was crucial in winning this order and it was sub-contracted to RiddWood Structural Engineers. Criteria such as slab thickness, concrete grade, re-bar location and specification, drainage routes, falls and detailed dimensions were all specified and presented. The structural slab was designed not only to support the chiller enclosure and pipe riser tower structure that it would underpin, but also to span across voids in the existing groundwork above a very large basement area and network of tunnels.

Structural design of all supporting steelwork and interfaces with the existing building

This was carried out by RiddWood Structural Engineers. Caice then undertook detailed design of the chiller enclosure and pipe riser tower considering all product and material interfaces.

Detailed design, manufacture and installation of chiller enclosure and pipe riser tower

Standing a total of 7m High, 23m long and 8m wide the chiller enclosure is a very large structure and nine London double decker buses could fit inside the space.

We manufactured and installed the acoustic panel enclosure, incorporating very large doors as well as the flexible plenums and intake and exhaust attenuators.

The pipe riser tower is 18m High, 3.5m Wide, 1m Deep at its narrowest point at low level then spanning back across the existing roof at high level to a depth of 5.2m. We designed this neat visual solution to disguise the tall, skinny, ungainly network of pipes and services. It took some careful consideration, structurally and with how it would interface with the existing building. Then we manufactured and installed the louvre cladding and sheet metal roof.

Rooftop access, radio waves and tight site access were challenges

Roof access and radio waves were a challenge so we purchased a Radio Frequency (RF) monitor and put our installation team through a two day training course to safely access the rooftop and to work with antennas emitting potentially dangerous radio waves.

Tight site access was a big issue. Due to the very narrow road to the side, we had to select a mobile crane that could be operated safely within these physical limitations as well as have the correct lifting capacity. The versatile, mobile Bocker Crane proved an ideal choice. It is a compact and lightweight truck mounted crane and has no ballast / body to rotate with the slew of the crane. Meaning it was far easier and safer to control and it also proved far more cost effective than the others explored.

Installation access and cranage by Caice

Site specific training was implemented. The Bocker Crane lifted the MG modular attenuators into position. The driver and signaller/lift supervisor worked together with the Caice installation team, who guided them into the designed position and performed fixing duties.

Tight access to the rear of the enclosure meant a large scaffold frame was used to fix attenuators and cladding to the rear face.

The tower was installed with the use of large cherry pickers.

The remaining panelling was installed by hand with the use of scissor lift and mobile tower access equipment. Telehandler forks moved material around the site as well as off-and-on-loading vehicles as required.

Fully trained team capable of working in other BT sites

We now have a fully trained team capable of working on other BT sites with similar requirements. A well put together enclosure and tower arrangement installed by a safely working installation team supported by a proven cranage solution for future projects.

Caice products and services provided

- MG modular Attenuators

- 75mm Acoustic Panel cladding

- Acoustic doors

- Flexible PVC plenum connections

- PLS.50 Architectural / Weather Louvre system

- Sheet metal roofing

- Secondary support steel framework & bracketry

- Polyester powder coat finish

- Site survey

- Design

- Project management

- Installation

- Access machinery

- Mobile cranage (contract lift)

- Waste removal

Do you need a total solution to a complex brief?

We provided a total solution to a complex brief and managed the whole of this project. Starting with understanding the specific issues, through the design stage, manufacture and safe installation with tight access, ending with waste removal from site. Professional project and service management, good team work and communication with a number of sub-contractors helped out within their specialist areas.