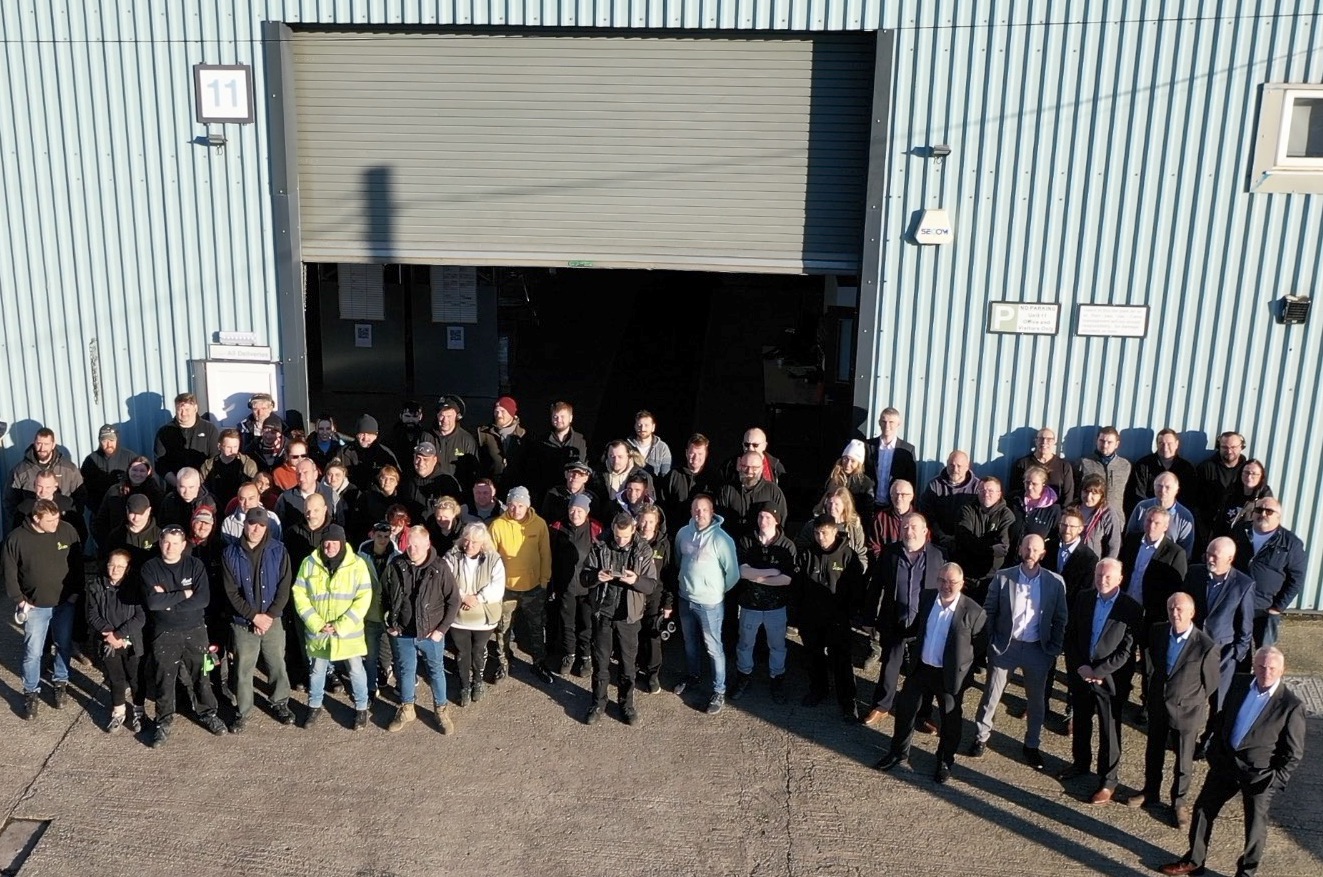

Fully Integrated Production Centre

4,800 sq m. of consolidated highly efficient space, powered by renewable energy from our solar panel array

Five buildings all in one shared location

In the South of England

Based on a long-standing presence in the South of England since 2000, we’ve now integrated our previously separate operations into one consolidated site, and a highly efficient Production Centre.

It consists of five buildings, including our Thermal and Acoustic Test Centre. All are next to each other on an industrial estate in Sturminster Newton, a vibrant market town in North Dorset.

Reaching your environmental, sustainability & carbon reduction targets

Our new Production Centre means that we can continue to drive down unnecessary costs, drive up manufacturing efficiencies, as well as reduce the embodied carbon in all of our products.

Which all goes towards helping our clients to reach their environmental, sustainability and carbon reduction targets.

“This exciting development further improves our operational efficiency and streamlines our manufacturing processes so that we can respond even more quickly to both our client needs and emerging trends in the construction industry.”

Paul Roebuck, Production Director at Caice.

£400,000 investment in Polyester Powder Coating line

- 300% increase in capacity to meet demand

- Superior chemical pretreatment achieved

- Increased durability of products

- On-going Quality Control at our on-site Test Laboratory

Excess heat recovered keeps us warm

None of the heat from the industrial oven in our powder coating line will be wasted. It will be reused, by putting it through a heat exchanger, improving energy efficiency and reducing the cost of keeping us warm at work.

Using water three times slashes consumption

Water in our powder coating line is reused for the first rinse in the chemical wash process. In the future it will be used a third time to flush toilets, drastically reducing our water consumption.

“This investment is all part of our on-going commitment to provide our clients in the construction industry with the highest quality products and services at competitive prices.”

Paul Roebuck, Production Director at Caice.

Choose from 200+ colours

Discover more about our five stage process for Polyester Powder Coating

50% less packaging used

To protect your products during transit and on-site, our robo-wrapper shrink-wraps them tighter than our most experienced people can achieve, so it is far more efficient, safer and uses 50% less plastic packaging.

0% waste to landfill

All our cardboard packaging, steel and insulation materials are recycled so zero goes to landfill. Everything else goes to our local Waste for Energy centre. Now that’s something to be proud of.

Biofuels reduce emissions & improve air quality

All our forklift trucks run on Liquid Petroleum Gas (LPG) which is cleaner more efficient and cheaper than diesel. Our delivery vehicles run on 20% biodiesel, which is a renewable, biodegradable fuel made from vegetable oils, animal fats and recycled greases. Reducing carbon emissions by more than 75% and improving air quality.

Powering our Production Centre with renewable energy makes a positive impact on the environment

Our solar panel array

Reduces our Carbon footprint by cutting our greenhouse gas emissions by over 42.5 tonnes of CO2 each year.

As 1,900 trees would be needed to absorb the same amount of CO2 emitted annually

Lowering our Carbon footprint

In a bid to reduce our carbon footprint we have installed a solar panel array at our Integrated Production Centre in Dorset, generating 192 KW of energy per annum, which provides the equivalent amount of energy to power 60 homes of average size.

Lower Embodied Carbon and lower energy bills

Switching to renewable energy is good

As one of the largest energy users in Sturminster Newton, switching to a renewable, eco-friendly source of power generated by solar panels will drastically reduce our carbon footprint as well as our energy bills. Because of the grant from Low Carbon Dorset we can install a larger number of solar panels than originally planned, which further reduces both our energy consumption and our carbon footprint.

By lowering the cost of energy used to manufacture our products, we also reduce the embodied carbon within them. Making them a more desirable and sustainable choice for our clients in their buildings. We can also continue to play a significant role in our community, by remaining the biggest employer in Sturminster Newton and surrounding area.

Helping to meet everyone's carbon reduction targets

Being a pioneer and market leading supplier of acoustic and air movement products to the construction industry and installing this solar panel array is yet another way to help our clients, employees and neighbours to meet their environmental, sustainability and carbon reduction targets.

Reducing Dorset's carbon footprint too

We’re helping reduce Dorset’s carbon footprint by installing a solar panel array on our Integrated Production Centre. Our project has been part funded by Low Carbon Dorset as part of the UK Government Shared Prosperity Fund and will save 42.5 tonnes tonnes of CO2 a year and Increasing renewable energy capacity in Dorset by 0.19173 Mega Watts at the same time.